Two Speed Manual Transmission

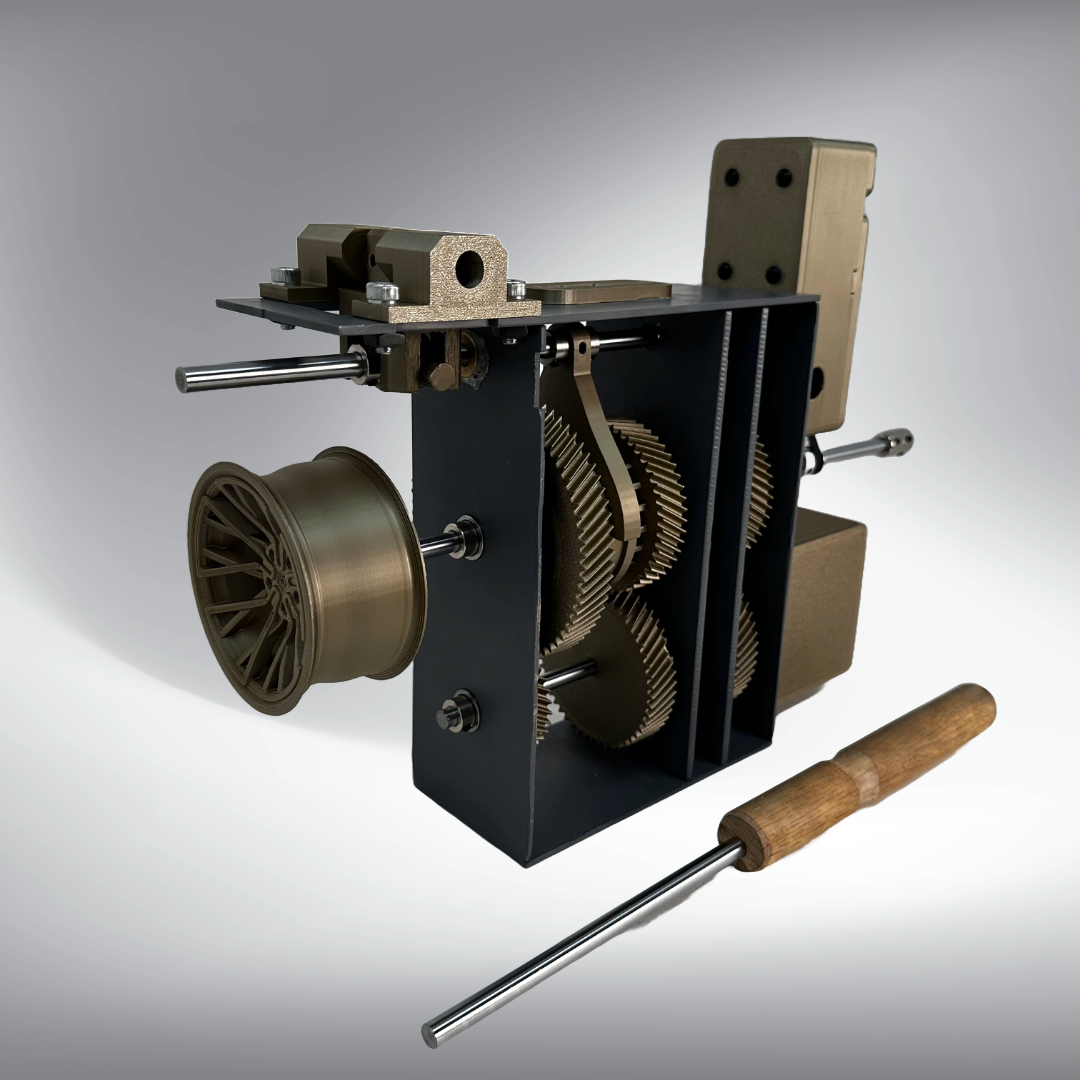

I designed and built a model of a simple two speed manual transmission. The objective of the project was to create a smooth mechanism with tight tolerances while learning about how a manual transmission functions.

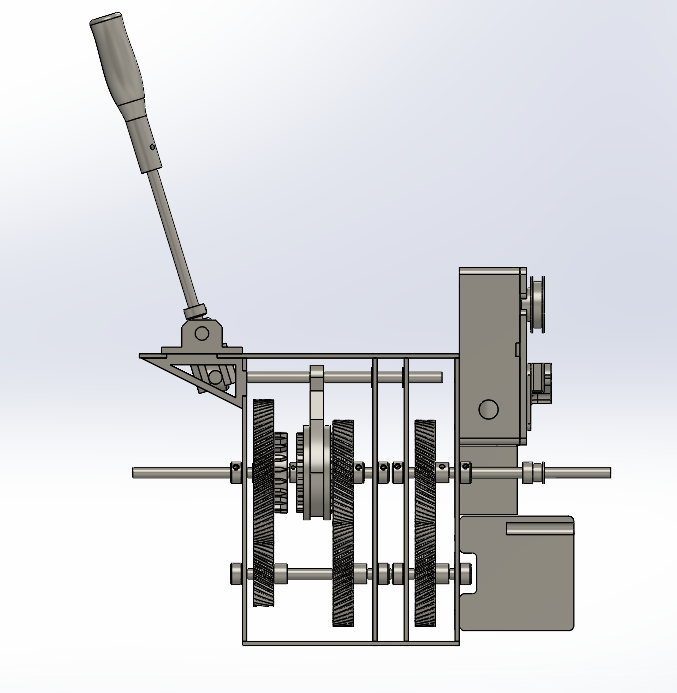

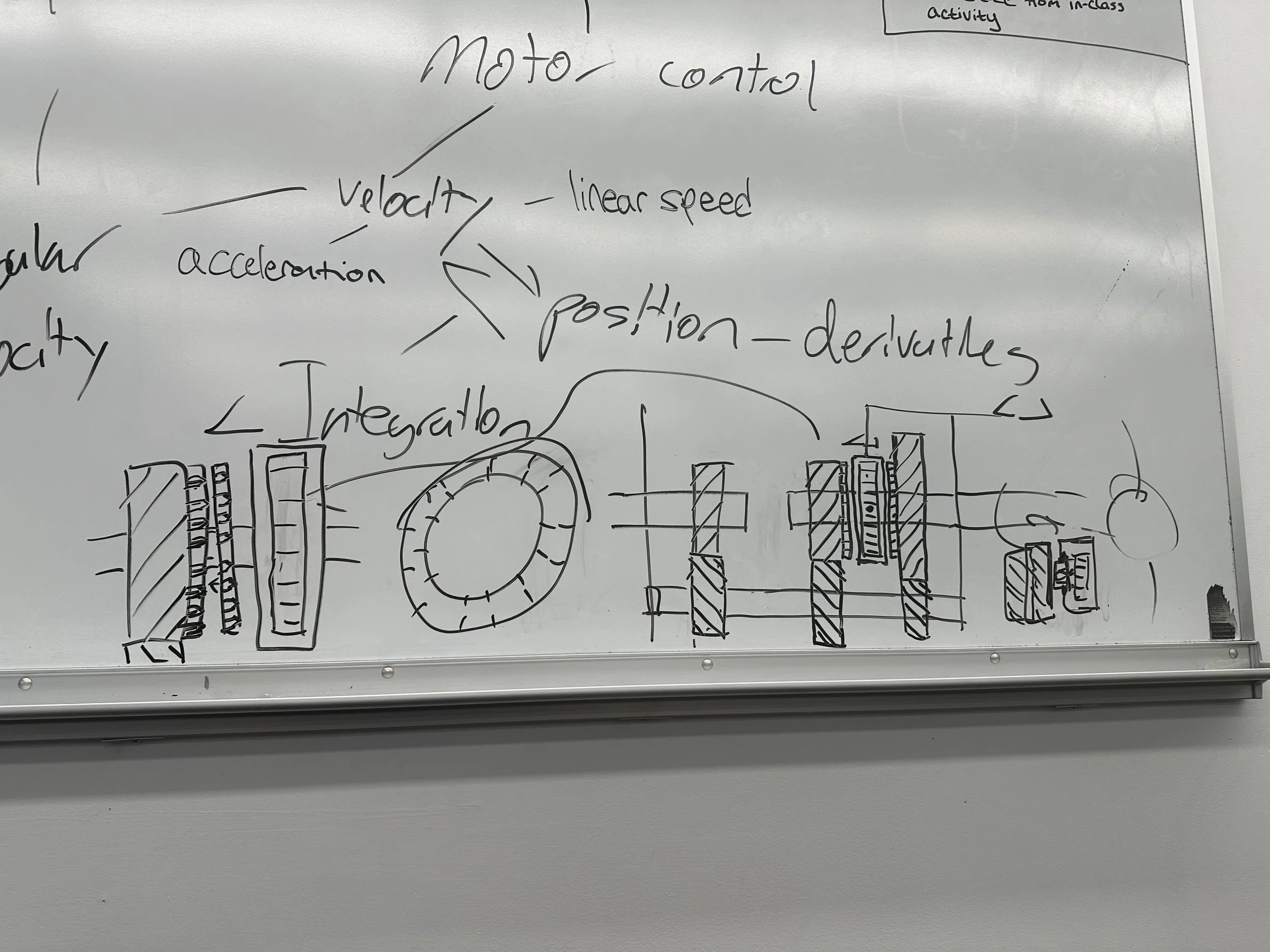

Prior to taking on this project I had no concept of how a manual transmission functioned, so I did research on several models of manual transmissions until I could design a similar mechanism on my own. This model functions by connecting the input and output shafts through a gear ring that can slide over gears with two differing ratios. A typical synchromesh that would be found in an actual manual transmission was not required as it would not have been functional due to material constraints as well as the low torque and speed inputs going through the transmission.

I was responsible for creating the internal gear mechanism as well as the shift mechanism. I designed the inner and outer selectors to slide easily over the helical gears and cause them to mesh with the output shaft. I also created the shift mechanism which translates the users gear shifts to translational motion and actuates the internal gears.

To fabricate the outer housing for the transmission I used the waterjet to cut the housing profiles and TIG welded them together to create the final housing. I then prepped it for paint with abrasives and painted it in the paint booth. All other components were preexisting hardware or 3D printed.