Formula FSAE

I joined the Formula FSAE Electric team at Olin College of Engineering in my first year because of my passion for automotive engineering. I have since gained a multitude of skills such as Solidworks CAD, suspension calculation & design, composites manufacturing, and metal fabrication.

Front Rocker Assembly

The front rocker is the component of the front suspension that transfers the force from the wheel travelling upwards to compress the shock and actuates the z-bar style anti roll bar.

I oversaw the design of the rocker using the requested suspension characteristics from our driver and calculated the optimal pickup points for the pull rod, shock, and ARB. The location of each component was optimized to maintain an acceptable shock to pull rod ratio throughout the full suspension travel.

Additionally, I collaborated with the student in charge of the front z-bar ARB to find a suitable pickup point that would provide sufficient force to put the bar in bending while not sacrificing factor of safety.

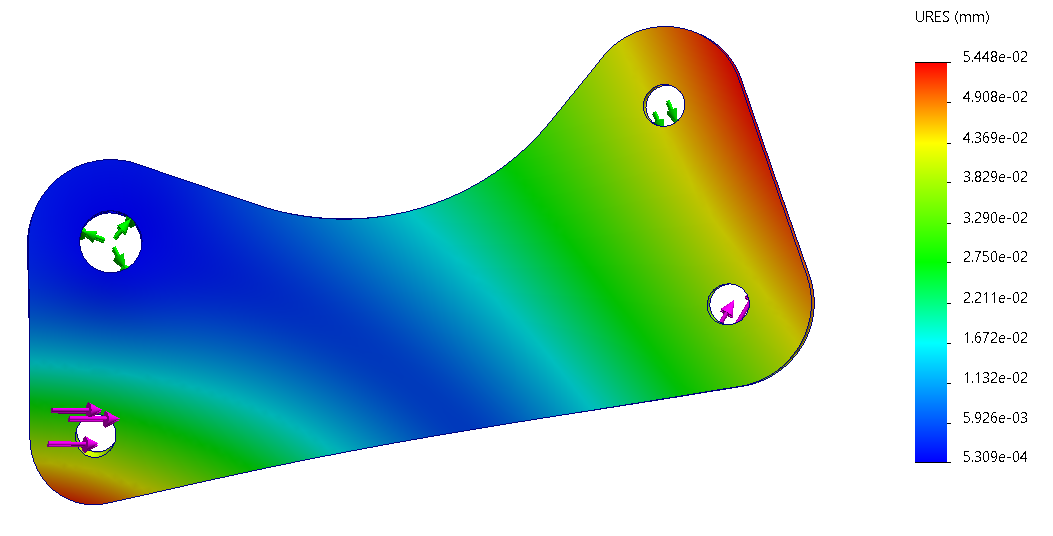

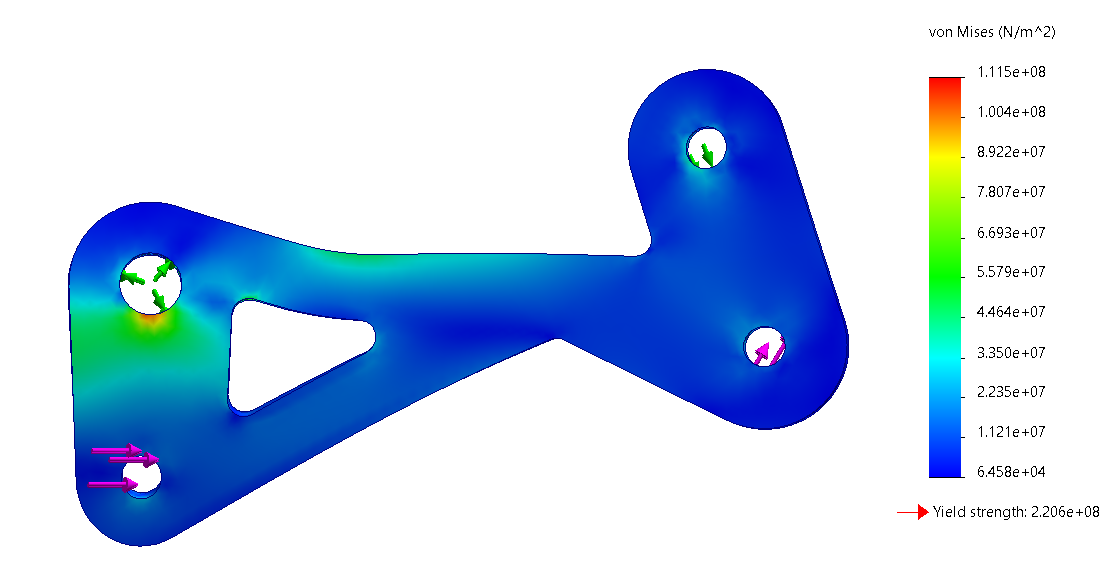

After finalizing the rocker geometry, I conducted a finite element analysis to ensure that the rocker would be structurally sound under full loading conditions. Additionally, I conducted a topology analysis on the rocker to achieve maximum weight reduction with a factor of safety of 2. I then conducted another FEA study with the new light weighted rocker to ensure that the part would not get close to failure under full load.

HEMP AERO

I worked on a team of five students to design a full custom aerodynamics package made out of sustainable hemp fiber for our MK6 FSAE Car.

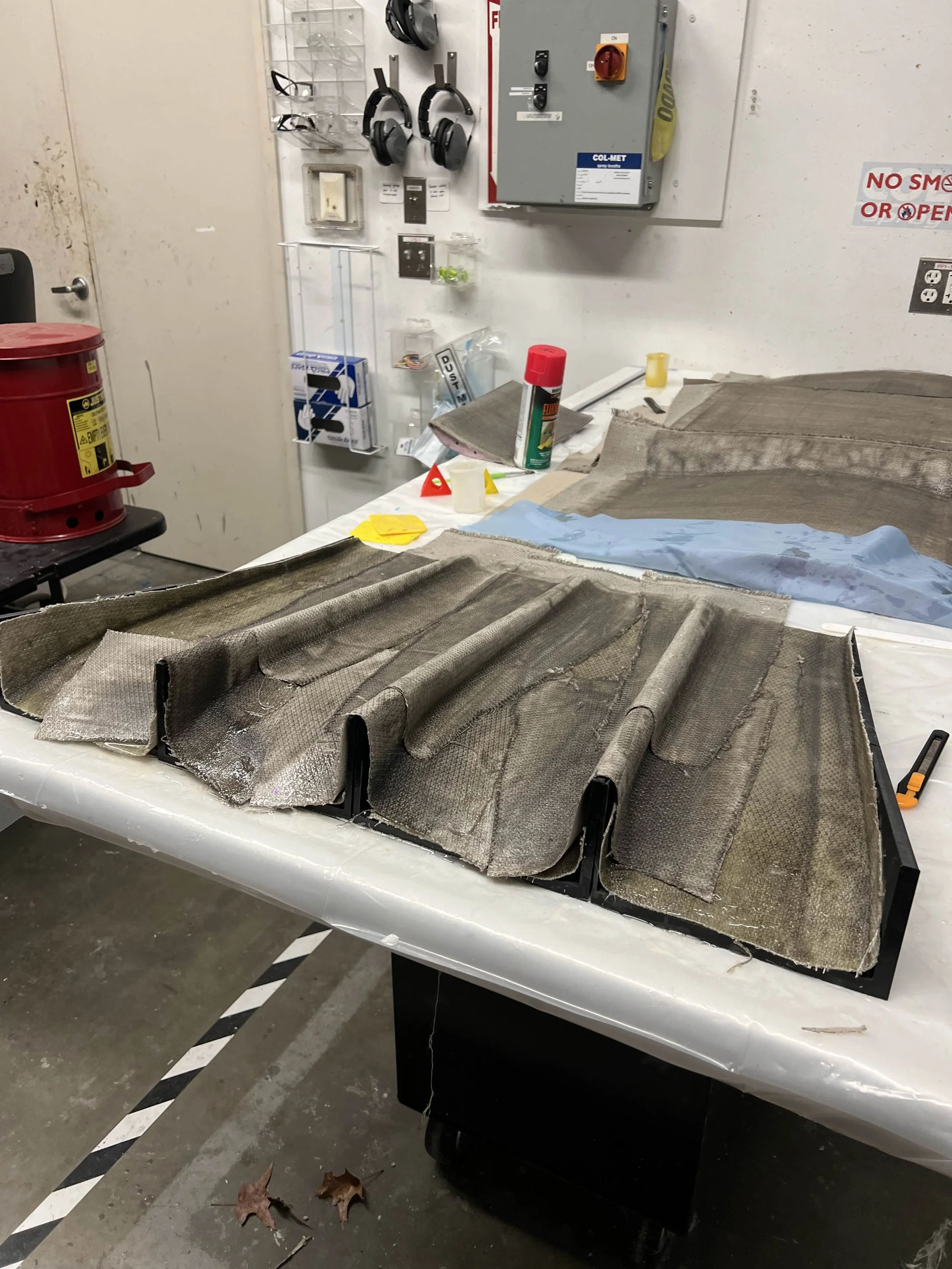

I was responsible for designing and fabricating the rear diffuser, an aerodynamic component that aims to create a low pressure zone underneath a vehicle to generate downforce by accelerating airflow exiting from beneath the car.

For the design of the diffuser I read about the aerodynamic principles that cause diffusers to generate downforce as well as took inspiration from rear diffusers in multiple motorsports disciplines such as Formula 1, time attack, and hill climb.

After CADing the diffuser using an equation driven curve within SolidWorks, we ran a simple Ansys simulation to test its effectiveness.

After validating the diffuser’s effectiveness and reaching design lock, I split the diffuser into easily 3D printable segments to create a printed mold for the hemp composite. I then laid the hemp fiber and resin combination over the mold to create the final diffuser.

Currently, I am working on the next iteration of our design to be implemented on MK8.

Click here for additional information about the project on the Olin College website.