2JZ Build and Swap

Since entering the world of automotive enthusiasts, I have always had the urge to create something truly unique. I decided to purchase a junkyard 2JZ-GE engine, rebuild it from the short block up, and swap it into my 2022 BRZ.

2JZ-GE Turbo Build

During my gap year prior to entering college, I purchased a junkyard 2JZ-GE engine with the intention to completely rebuild it and eventually swap it into my car. I began by doing research on which engine I wanted to build and settled on the GE as it was in the JZ family but was reasonably affordable.

I completely stripped the engine down to the bare block and head and sent them to a machine shop to be bored and honed. After receiving the engine back from the shop, I installed the aftermarket pistons and rings, connecting rods, main and rod bearings, and various sensors. During this entire process I needed to pay close attention to details such as piston ring clearances, main bearing clearance, and torque specifications.

After finishing the bottom end of the engine, I installed the aftermarket valves, valve springs, buckets, and cams alongside various other components into the engine head. I needed to ensure proper valve to bucket clearance by measuring each individual gap with a feeler gauge.

Finally, the engine assembly was finished in reverse order of initial disassembly as accessory components such as the water pump and alternator were installed. To install a turbo setup, I needed to create custom oil feed pathways and a drain port on the engine which I did so by tapping into an existing oil feed and creating a drain location on the upper oil pan.

Engine Swap

Soon after the engine was rebuilt, I removed my previous engine from my 2022 BRZ. Going into the engine swap process with no prior experience a lot of online research and in person consultation was necessary.

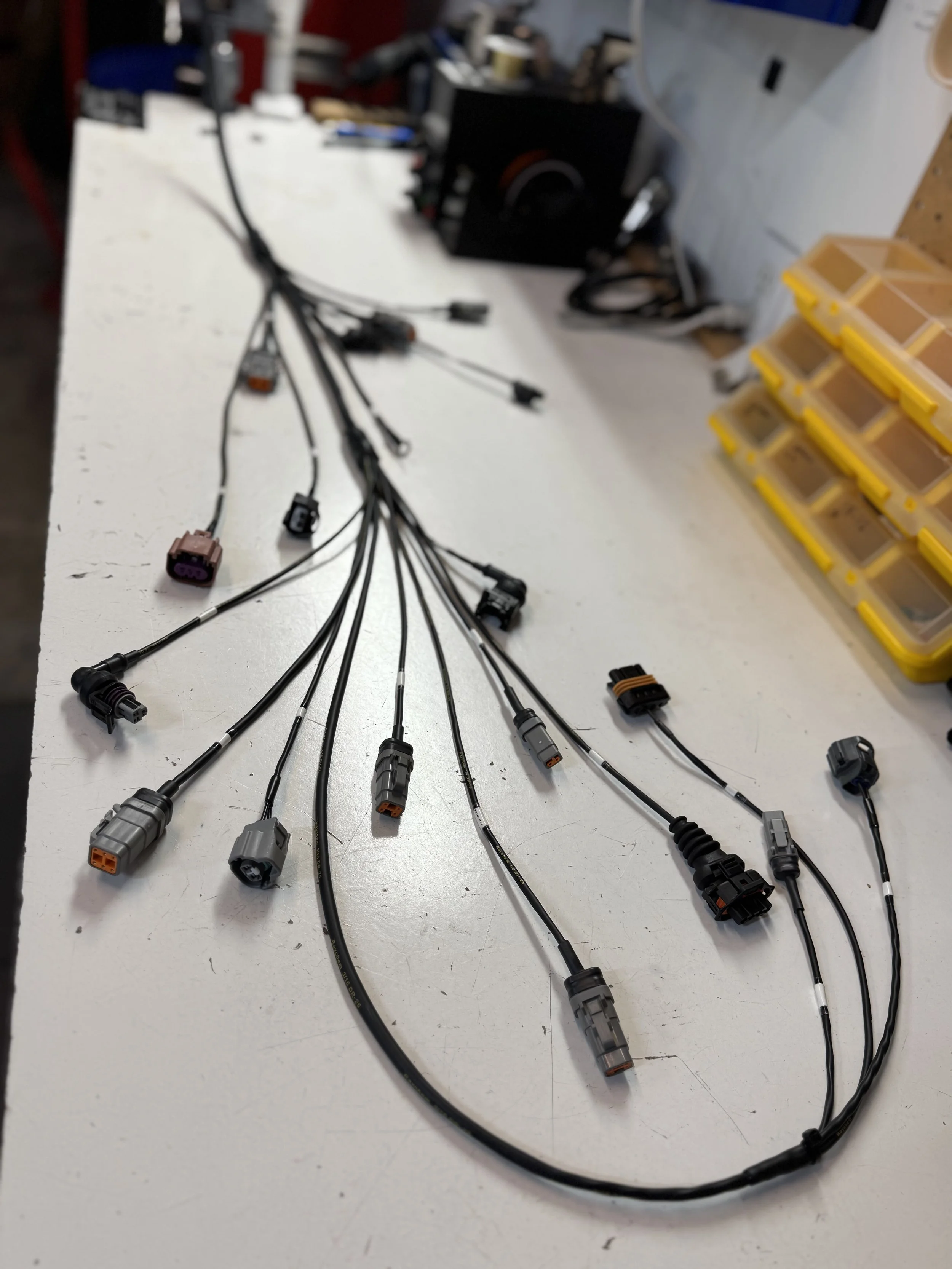

All coolant, electrical, and air conditioning lines were removed and the engine was lifted out of the car. Custom engine and accessory mounts were created in order to test fit the 2JZ in the new chassis. Extensive modifications were necessary for the transmission tunnel and firewall in order to mount the engine as far back and low as possible to maintain optimal center of mass. All parts of the drivetrain, including the transmission, driveshaft, differential, and axles, were swapped out to accommodate the increased power levels of the new engine. The fuel system from the fuel tank upwards were replaced with custom AN lines and aftermarket fuel hardware. A custom coolant loop and oil cooler system was created with greater cooling capacity to ensure that the engine runs smoothly under increased load. Finally, custom intercooler mounts and piping were fabricated to finalize the forced induction system.