Automatic Pool Cue

I worked with a team of four students to develop an easy to use and robust automatic pool cue.

The objective of this project was to create a automatic pool cue that would both have enough force to propel pool balls a sufficient distance as well as package it all within a lightweight and portable package.

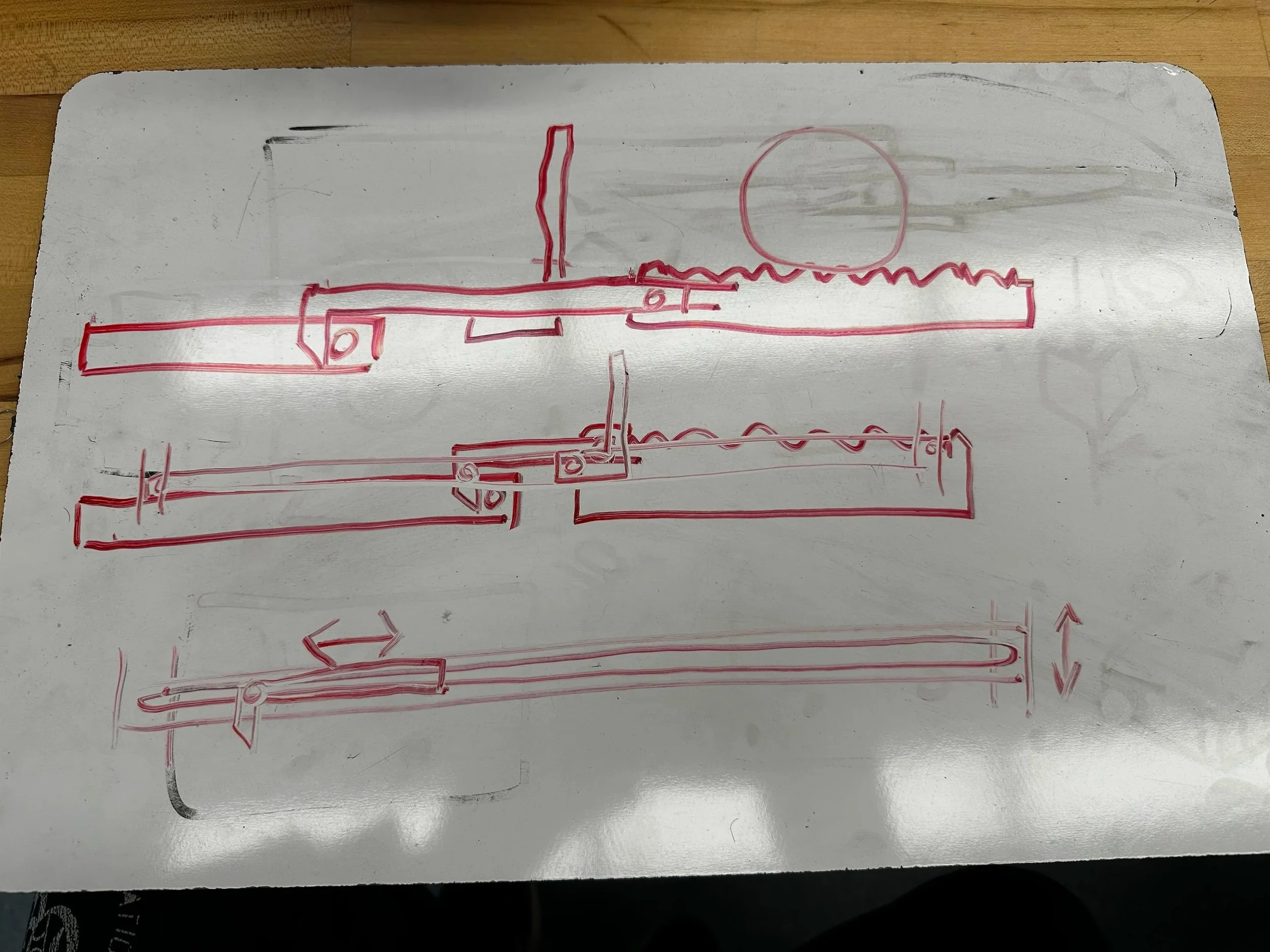

I was responsible for designing and fabricating the variable trigger. Since in pool one needs to adjust the amount of force used within a shot, the trigger of our automatic pool cue needed to have the ability to release the cue at any point within the draw distance. I created a rail along which the trigger latch slides and can be pulled up no matter how far drawn the cue itself is.

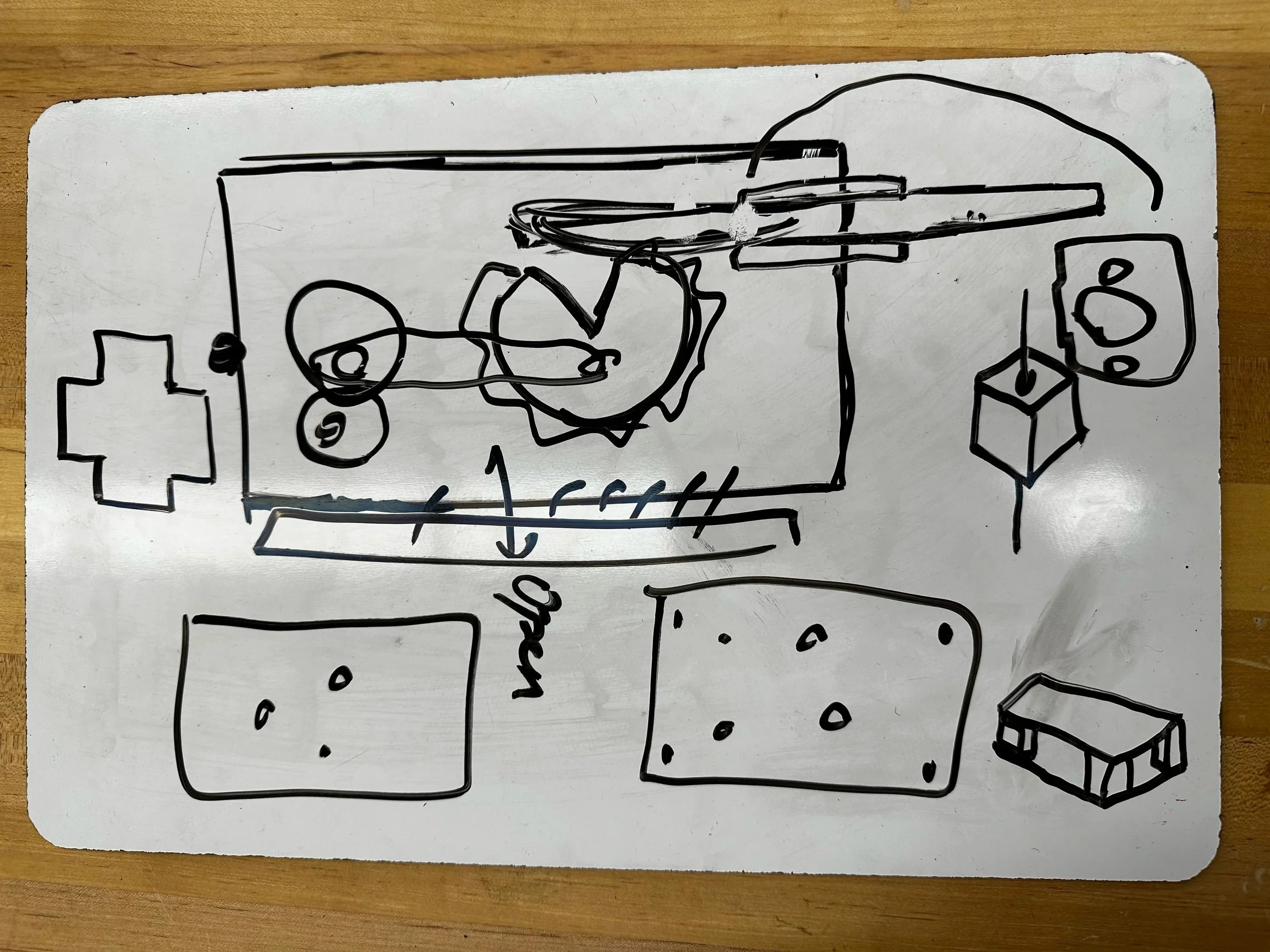

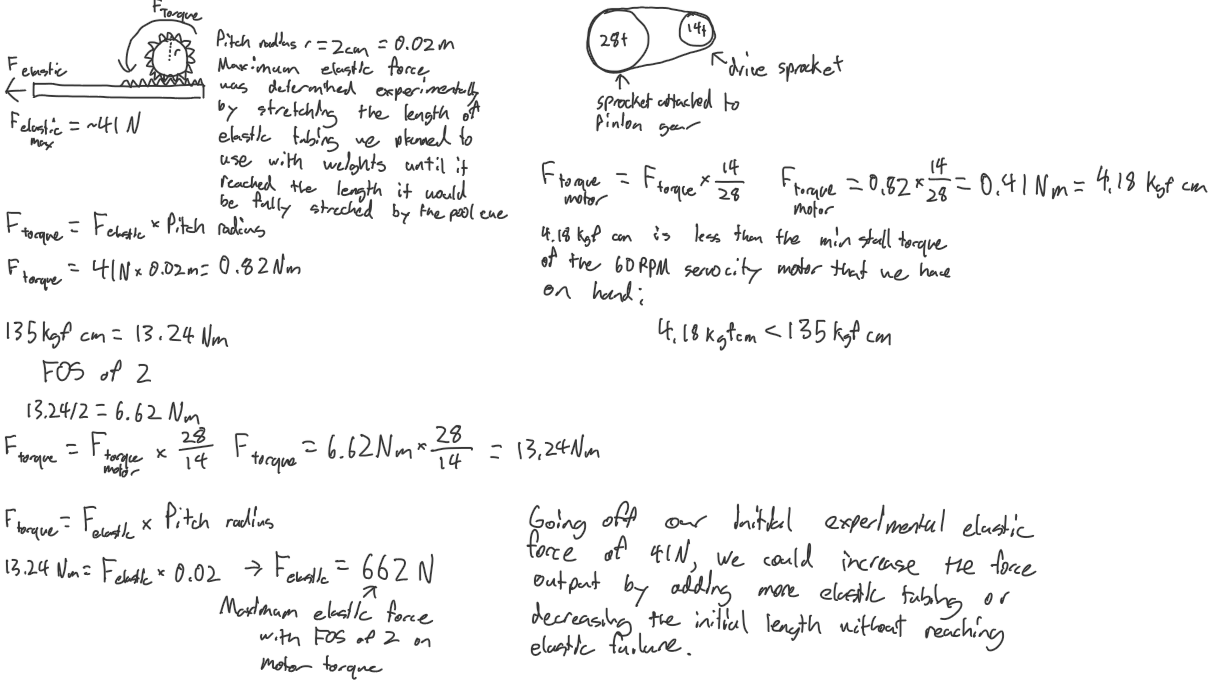

In the gallery below you can see my sketching and ideation process for coming up with the final trigger design as well as hand calculations I did to validate our drivetrain components.

After modeling all components in a SolidWorks assembly, I began to machine the parts necessary for the pool cue. For the front and motor mounting panel, we chose to waterjet the profiles out of aluminum as those sides would need to remain rigid under forces that would cause acrylic to yield.

I CNC milled the variable trigger components out of aluminum as they would also be subject to relatively high forces that 3D printed parts would not be able to sustain.

After machining all critical mechanical components, I lathed each standoff/spacer out of spare aluminum stock for aesthetic purposes.

Finally, we assembled the pool cue using standard metric hardware.

To the left is a video of the mechanism working and another video we made for fun to showcase our project.